Our Services

We will help you increase efficiency and reduce costs.

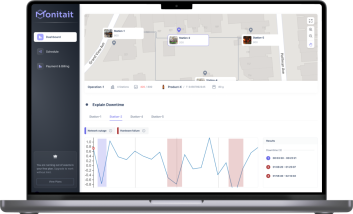

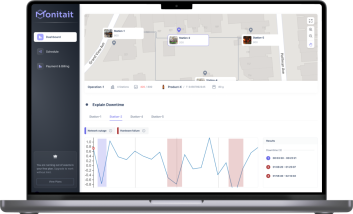

Production Line Monitoring

We provide real-time insights into production line performance, identify bottlenecks, and optimize operational efficiency. By analyzing production data, our systems calculate OEE metrics and help businesses identify areas for improvement, leading to increased productivity and reduced downtime.

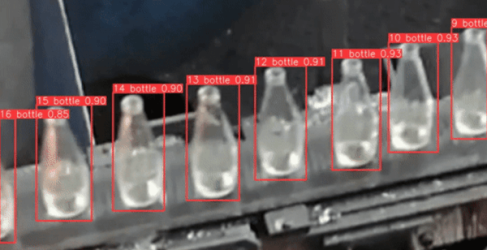

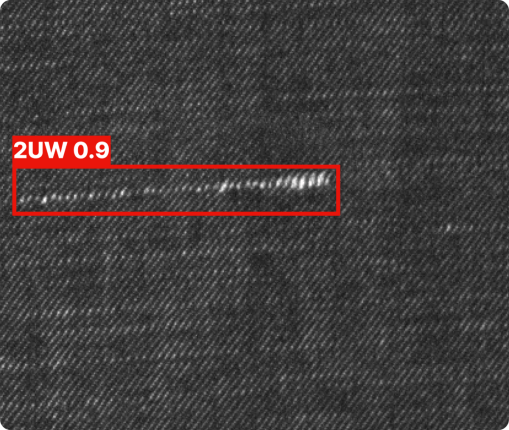

Quality Contro

By combining advanced image processing techniques with artificial intelligence, we enable companies to detect defects, anomalies, and variations in their products with exceptional accuracy.

Data Labeling

Our labeling tool connects employers and workers globally to complete labeling tasks faster, more efficiently, and more cost-effective.

Workplace Safety Solutions

We utilize machine learning algorithms to detect potential hazards and safety risks in real time. This helps businesses prevent accidents, reduce injuries, and maintain a secure working environment by warning users about potential dangers.

Data Mining for Efficiency Enhancement

Our AI algorithms analyze production data, identify patterns, correlations, and anomalies, and provide valuable insights to drive operational efficiency.

Our Solutions for The Glass Industry:

A customized path toward productivity!

Proactive Maintenance and Downtime Reduction

By monitoring machine performance and collecting key parameters, anomalies are detected early on. This allows for scheduled preventive maintenance, minimizing breakdowns and reducing downtime.

Streamlined Data Gathering and Integration

Automatic data gathering systems capture data from sensors, machinery, PLCs, and manual entry. This seamless integration provides a comprehensive view of the production process, enabling accurate OEE calculations and minimizing errors.

Data-Driven Decision-Making for Process Optimization

Analyzing historical trends helps identify patterns and areas for improvement. Data-driven decisions optimize production parameters, streamline workflows, and minimize waste.

Driving Efficiency in Glass Manufacturing:

A Remarkable Journey

In today's fast-paced industrial landscape, optimizing production efficiency is a top priority for businesses.

This success story highlights the transformative impact of adopting automatic data gathering, real-time dashboards, and Overall Equipment Effectiveness (OEE) calculation in a glass manufacturing factory.

Driving Efficiency in Glass Manufacturing:

A Remarkable Journey

In today's fast-paced industrial landscape, optimizing production efficiency is a top priority for businesses.

This success story highlights the transformative impact of adopting automatic data gathering, real-time dashboards, and Overall Equipment Effectiveness (OEE) calculation in a glass manufacturing factory.

Call Us!

+96871932838

Chat with Our Experts.

??

Write An Email.

contact@smartfalcon.com