Automatic Inspection and Real-Time Visibility

The integration of automatic inspection with custom AI models and real-time visibility offers significant benefits to manufacturers in sectors like cement and concrete.

Construction Material

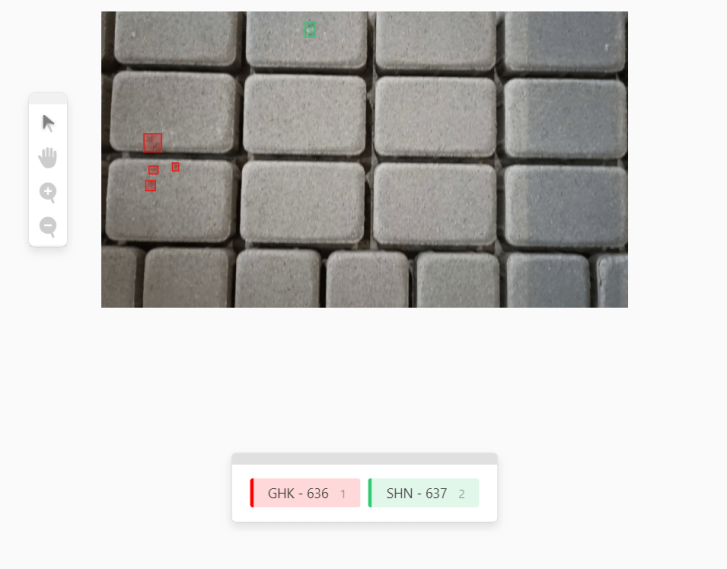

Camera-Based Visual Inspection

By utilizing advanced cameras, defects and anomalies in cement and concrete can be precisely detected during the production process. These systems capture detailed images, allowing for thorough analysis and identification of anomalies such as cracks, color inconsistencies, or surface irregularities.

Elimination of Manual Reports and Human Errors

With camera-based visual inspection and AI models, defects are automatically captured and documented in real-time. This digital approach streamlines the reporting process, ensuring accuracy and facilitating efficient defect analysis and resolution. Eliminating manual reports saves time, improves traceability, and enhances overall productivity.

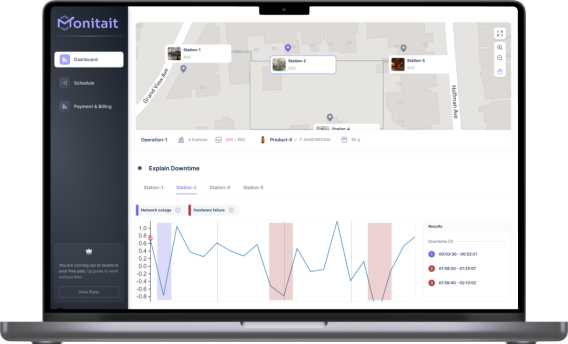

Real-Time Visibility for Continuous Improvement

By integrating automatic inspection systems with real-time dashboards, manufacturers gain immediate visibility into defect data, production metrics, and quality indicators. Real-time dashboards enable quick identification of trends, patterns, and potential areas for improvement. This visibility empowers manufacturers to take proactive actions, optimize processes, and continuously enhance efficiency and product quality.