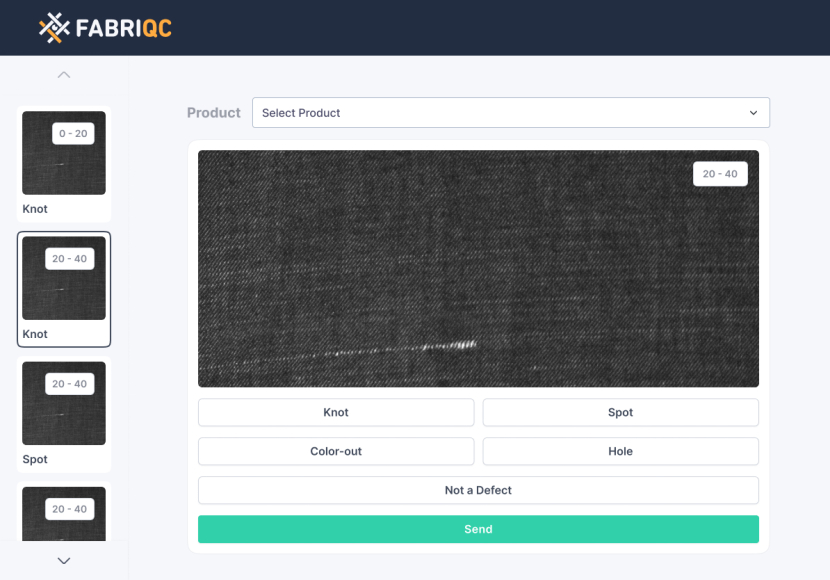

Smart Quality Inspection

By integrating manual checks with advanced image processing and machine learning, FabriQC help factories detect defects in real time, reduce human error, and ensure consistent product quality.

Real-time Defect Detection

AI-powered fabric inspection systems leverage real-time defect detction and provide comprehensive visibility into the operator.

The real-time defect detection through dashboards present detailed insights into quality metrics, highlighting any deviations or anomalies.

Personalized Certificates for Each Fabric Roll

We can automatically record relevant information, including inspection results, defect analysis, and images to provide personalized certificates for each fabric roll.

These certificates serve as proof of quality and instill confidence in customers, enhancing their satisfaction and reinforcing trust in the brand.

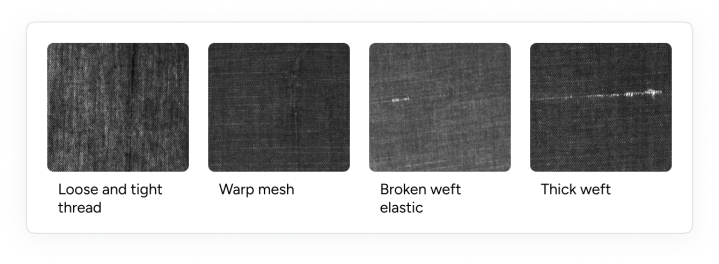

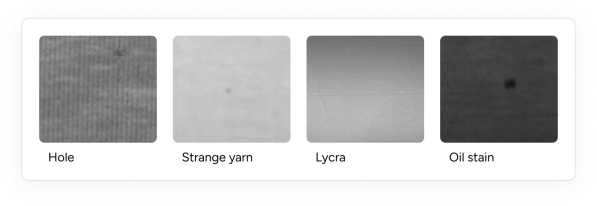

Flexible System for New Defects and Products

AI-powered fabric inspection systems provide a flexible framework to adapt to changes.

Manufacturers can train the AI models to detect and classify new defect types or develop models for new fabric products efficiently.

This flexibility ensures that the fabric inspection system remains up-to-date, accommodating evolving market demands and maintaining high-quality standards.