Automatic Data Gathering with IIoT Devices and Anomaly Alerts for Immediate Response

The integration of automatic data gathering through Industrial Internet of Things (IIoT) devices offers tremendous benefits by providing real-time access to machine data from different zones of the factory on a unified dashboard.

Tire Industry

Real-Time Dashboards for Enhanced Visibility

These dashboards offer a comprehensive overview of machine performance, production metrics, and key indicators in a unified interface. Operators, supervisors, and managers can monitor the status of machines, track production volumes, and identify any anomalies or performance deviations in real-time.

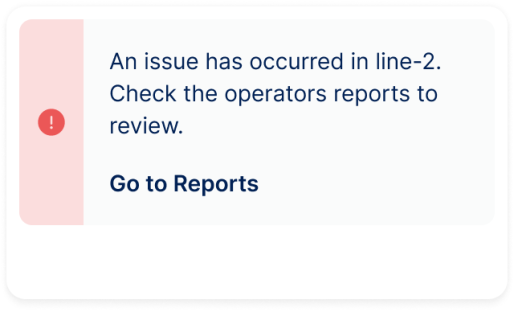

Anomaly Alerts for Immediate Response

IIoT devices capture signals and data from machines, sensors, and PLCs in real-time. By leveraging AI algorithms and analytics, manufacturers can set up anomaly detection systems that generate alerts when deviations from normal operating conditions occur.

These alerts enable operators to take immediate corrective actions, preventing potential issues, minimizing downtime, and ensuring uninterrupted production.

Data-Driven Decision-Making for Process Optimization

Analyzing historical trends helps identify patterns and areas for improvement. Data-driven decisions optimize production parameters, streamline workflows, and minimize waste.